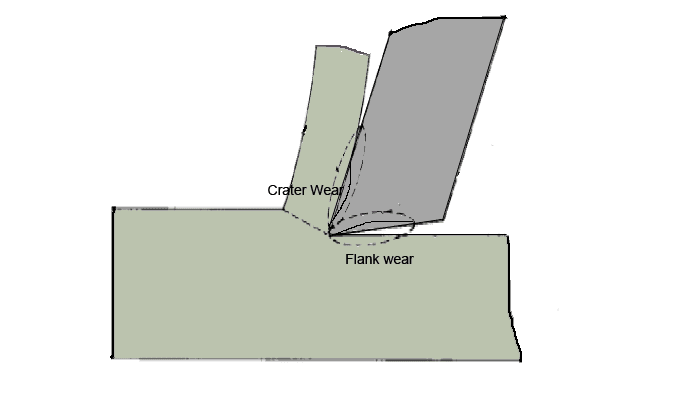

Classification of a worn cutting tool showing crater wear, flank wear... | Download Scientific Diagram

Wit GRZESIK1 INVESTIGATION OF NOTCH WEAR MECHANISMS IN THE MACHINING OF NICKEL-BASED INCONEL 718 ALLOY 1. INTRODUCTION Wider ap

Notch wear prediction model in turning of Inconel 718 with ceramic tools considering the influence of work hardened layer - ScienceDirect

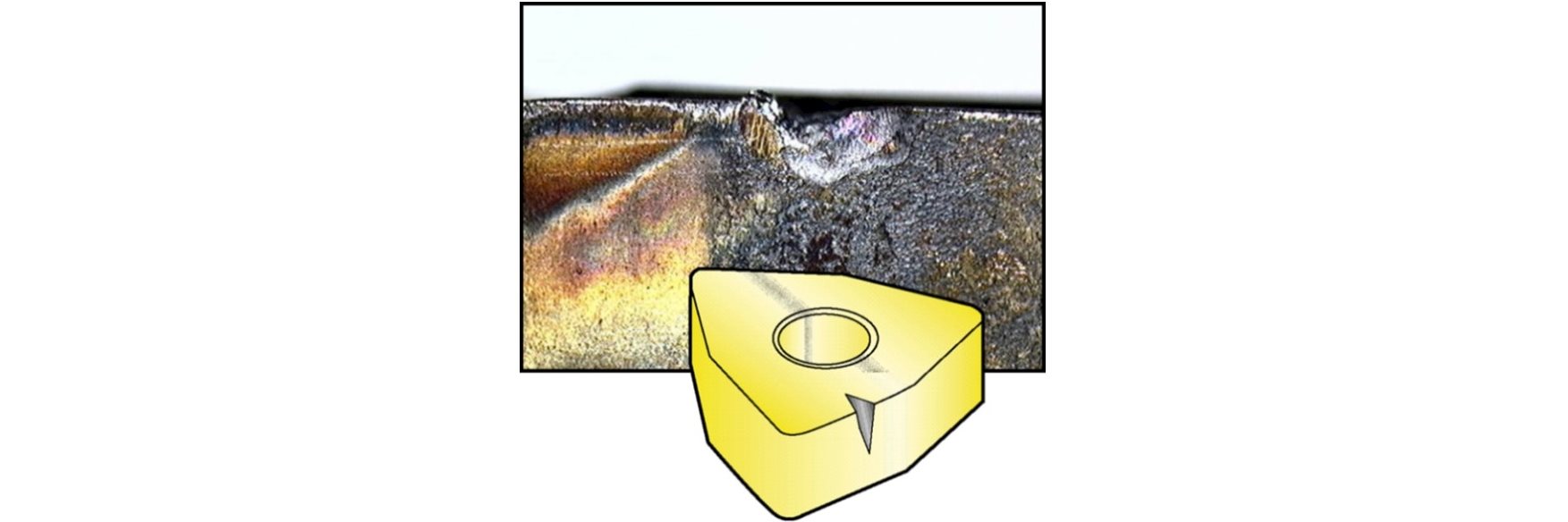

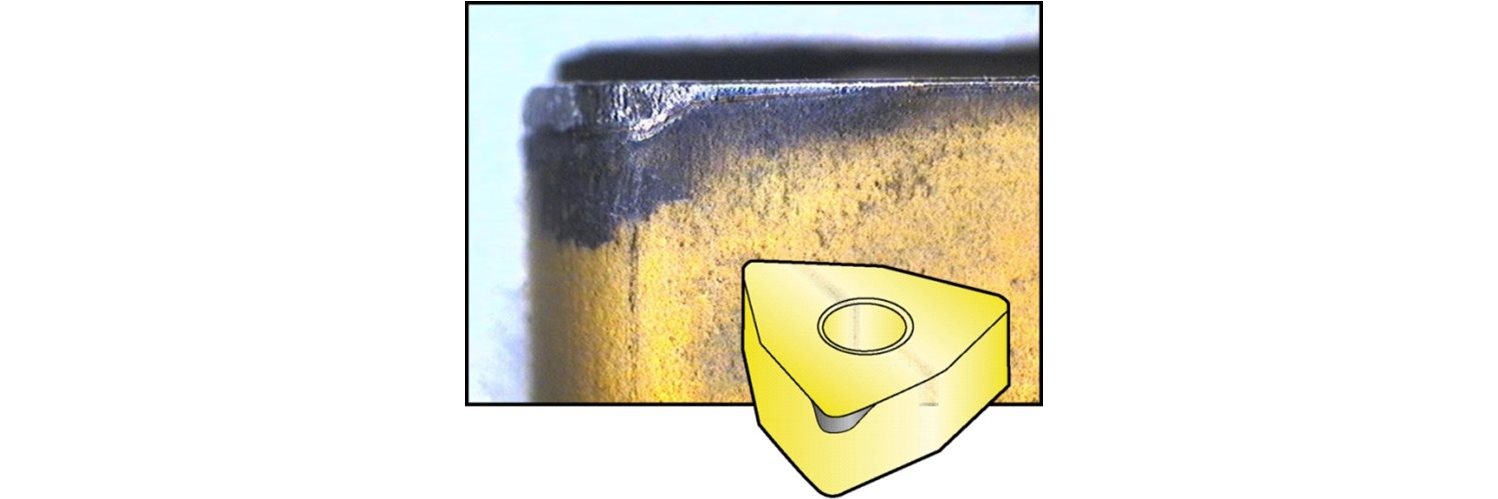

Flank wear, notch wear and crater wear zone for the cubic boron nitride... | Download Scientific Diagram

Suppressing notch wear by changing the tool path in the side milling of a Ti-6Al-4 V alloy | SpringerLink

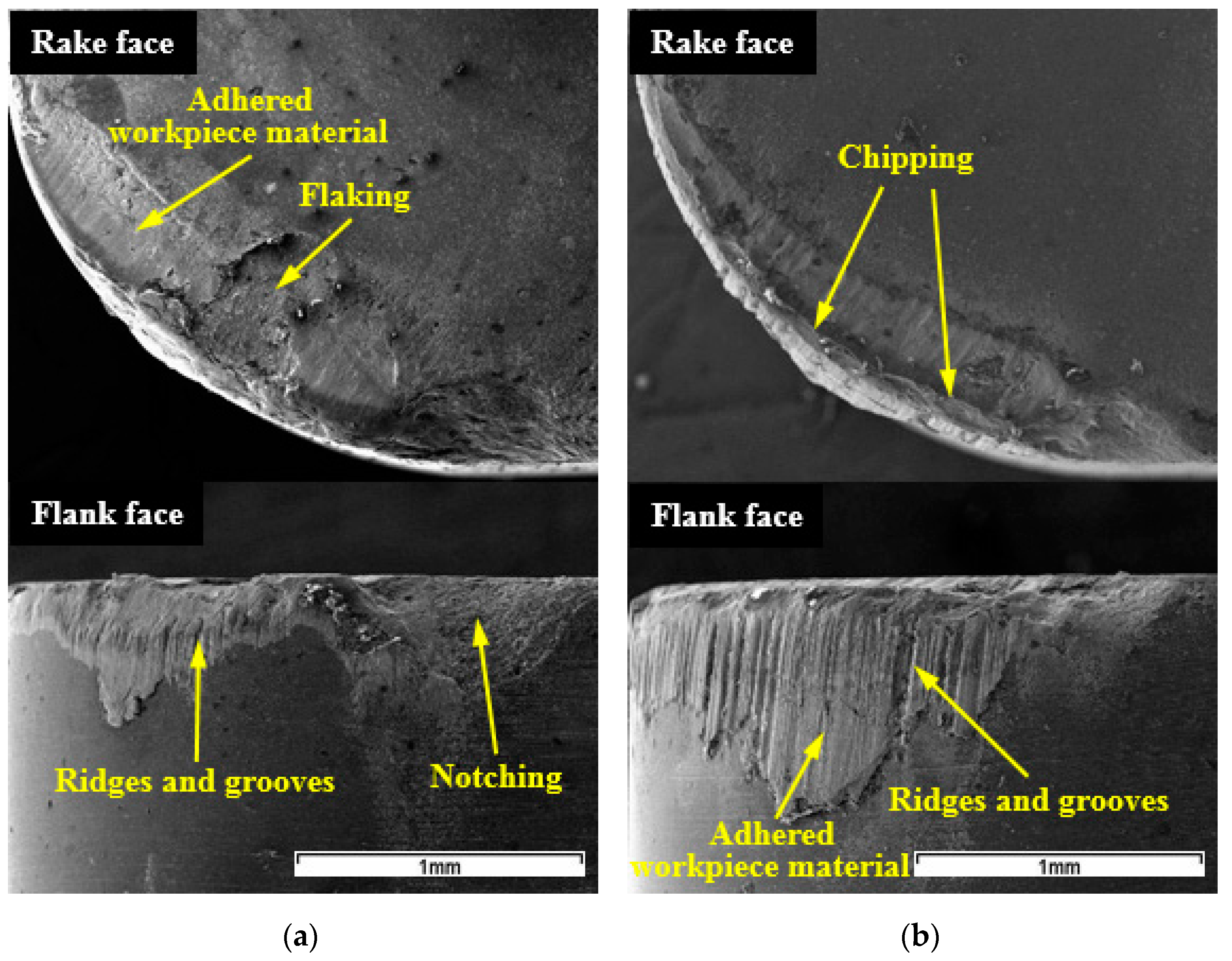

Materials | Free Full-Text | Wear Mechanisms and Notch Formation of Whisker-Reinforced Alumina and Sialon Ceramic Tools during High-Speed Turning of Inconel 718

Notch wear prediction model in turning of Inconel 718 with ceramic tools considering the influence of work hardened layer - ScienceDirect